Steel Built to Withstand Any Challenge

Hardox HiAce

The real proofs of Hardox® HiAce: 70% reduced maintenance, outperforms stainless steel.

Meet the new ace in corrosion-resistant wear steel for acidic and humid environments. In environments where corrosive wear destroys ordinary steel, Hardox® HiAce stands its ground. Engineered to combat corrosion in the toughest settings—from waste and recycling to wood, pulp and paper—this high-performance wear plate delivers extended service life, lower maintenance costs, and unmatched durability. Count on it to last. Anywhere. Anytime. For as long as the job demands.n the most punishing environments, steel equipment faces constant attack—from acids, humidity, sulfates, chlorides, ammonia, and other aggressive substances. Household waste, wood chips, manure, potash, and other by-products of industrial processes all pose unique chemical challenges that accelerate corrosion and wear. Hardox® HiAce has a specialized composition that resists corrosive wear in diverse environments

Hardox HiTemp

Hardox® HiTemp is a high-heat grade of Hardox® wear plate.

It provides a cost-efficient solution for wear resistance at high temperatures up to 500°C (930°F) with a nominal hardness of 400 HBW. When traditional quenched and tempered wear-resistant steels lose hardness at higher temperatures, Hardox® HiTemp steel still delivers high wear resistance.If you need to build heavy equipment that can fight wear in tough, high-temperature applications, take a look at Hardox® HiTemp wear resistant steel. While traditional Q&T wear-resistant steels experience a loss of hardness at temperatures of 300-500°C (about 570-930°F), this high temp metal stays strong and hard to improve performance and extend the service life of costly equipment.The outstanding performance of this heat resistant material is achieved by using high-quality raw material combined with a carefully controlled manufacturing process

Hardox 400

Hardox® 400 is an all-around steel that resists wear and abrasion with a nominal hardness of 400 HBW.

Hardox® 400 is a trusted steel in the Hardox® wear plate family, with a heritage of hardness and toughness going all the way back to 1974, when Hardox® was launched as the world’s first bendable wear steel. This allowed for reliable performance both in the workshop and in operation. Plates in Hardox® 400 come in thicknesses from 2 to 130 mm (0.079 to 5.118”).

Mild steel just doesn’t cut it in today’s equipment. It’s not strong enough, or hard enough to deliver the productivity or service life you expect. When you upgrade from steels such as S255, S355, A36, grade 50 or A514, SS400 or S45C to Hardox® 400, you can look forward to stronger and lighter equipment with higher capacity and less maintenance.

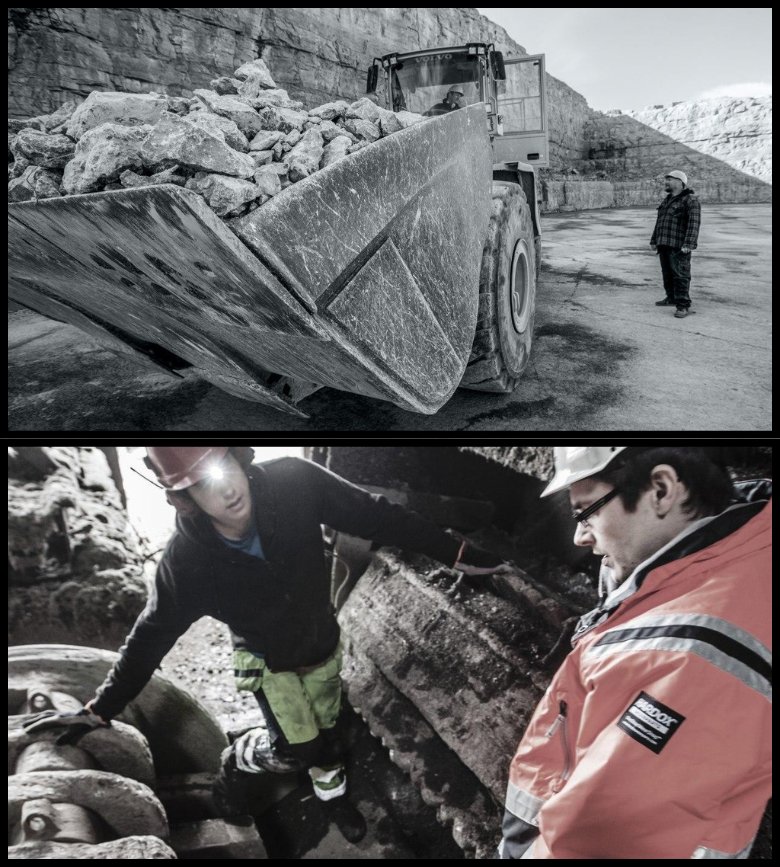

Hardox 500 Tuf

Hardox® 500 Tuf wear plate, the latest grade in the Hardox range, delivers exceptional strength, hardness and toughness in a single plate, guaranteed

It has proven its value around the world in tipper and dump bodies, containers, mining equipment, agricultural machinery, liners and wear parts, and buckets of all kinds. Explore the heavy wear fighter Hardox® 500 Tuf.

Increase payload and service life for buckets, dippers and attachments in Hardox® 500 Tuf,If you want productivity gains, nothing beats the combo of high strength, hardness and toughness that Hardox® 500 Tuf brings. And you won’t get bogged down with heavy wear packages or costly repairs because your attachments will last longer – potentially, up to 100% longer compared to using a 400 Brinell steel or conventional AR steel.

Hardox 550

Hardox® 550, with a nominal hardness of 550 HBW, offers a unique combination of excellent abrasion resistance, crack integrity and workshop performance.

Hardox® 550 is specially designed for heavy wear applications and makes a great alternative to 12% manganese steel castings, 500 Brinell wear plate or bimetals. The additional 50 Brinell you gain in hardness, when upgrading from conventional 500 HBW steels, will increase wear life, though not at the expense of crack integrity. Hardox® 550 is typically used for wear parts in industries like mining, quarrying, mineral processing, earthmoving and recycling.

- Makes a great alternative to grades with a lower hardness, conventional 500 Brinell steel plate, manganese steel castings or bimetals

- Risks of cracking minimized thanks to its high toughness and excellent surface finish